- Food

- >

- reinigen

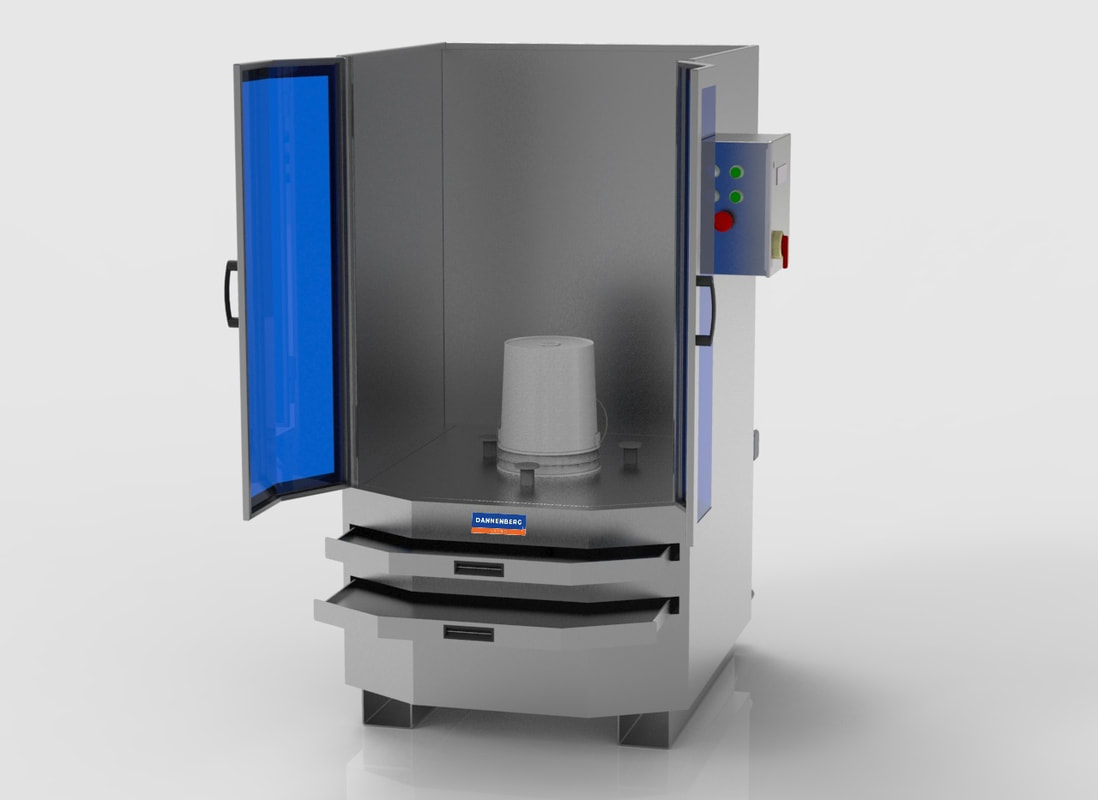

Stainless Steel Drum Washing Machine TYPE DWSStainless Steel Drum Washing Machine TYPE DWS

Introducing Dannenberg Industries' revolutionary Drum Washing Machine – where innovation meets efficiency in industrial cleaning solutions. Our cutting-edge machine is meticulously crafted to redefine how you handle and maintain drums, ensuring a seamless and thorough washing process. With advanced features tailored to meet the demands of modern industry standards, our Drum Washing Machine is designed for optimal performance. It boasts a user-friendly interface, ensuring ease of operation while maintaining a high level of precision in cleaning. From chemicals to oils, our machine handles various substances with utmost effectiveness. What sets Dannenberg Industries apart is our commitment to sustainability. The Drum Washing Machine is designed to minimize water and energy consumption without compromising on the cleaning power. This not only aligns with environmental goals but also contributes to significant cost savings for your operations. Trust Dannenberg Industries to elevate your drum cleaning processes. With our Drum Washing Machine, you're not just investing in a piece of equipment; you're investing in a cleaner, greener, and more efficient future for your industrial operations. Contact us today and experience the next level in drum washing technology |

|

Store drums or buckets upside down above the spray nozzle inside the machine for optimal cleaning. Once the doors are closed, initiate the spray cycle, with the adjustable spray nozzle catering to your desired height. Customize the spray time based on the drum/bucket size using the timer feature. To prevent any lifting during the spray, securely place the bucket on the platform.

Efficiently manage spray water by allowing it to flow back into the reservoir, passing through easily cleanable filters that can be stored conveniently in drawers. External cleaning of bucket exteriors is made effortless with the adjustable spray nozzle attached to an external hose. Maintain the reservoir's water level seamlessly through the use of a flutter mechanism. With Dannenberg Industries' advanced design, streamline your cleaning processes for drums and buckets, ensuring not just cleanliness but also ease of maintenance. |

|

Material frame: stainless steel (AISI 304)

Control box: IP65 Capacity: 45 drums/hour Spray time: adjustable Required water pressure: min 1.5 bar Max temperature of washing-water: 70° C Water consumption: approx. 30 liters/drum Electrical power installed: 3 kW Electrical current 400 V + 5%, 3 ph, 50 Hz filter : 2 sleef filter oilfilter: optional |

|

|

|

|